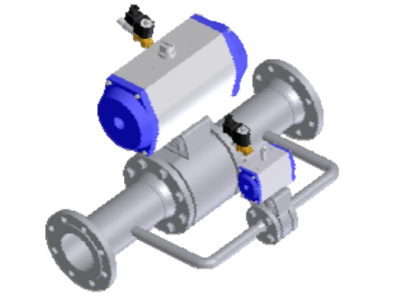

Oil Dosing Meter OKTronic

SKU: oktronic

Manufacturer: Bopp Reuther

pdf datasheet

DOSING METER OK-TRONIC

- Oval wheel meter with high accuracy

- also available with Massflow Meter

- Flow dosing computer DC155 for comfortable handling

- 2 step shut down

- metering for high viscosity (up to 10000 mPa·s)

- measuring of non-conductive liquids

- no need of inlet or outlet section

- Menu driven configuration

- also available for Ex-zone

Dosing Controller DC 155 for hazardous area

- mounting inside of hazardous area zone 1

- Ex-protection EEX ib IIC T6

- Solid housing protection IP 65

- Universal dosing control functions:

- with digital solenoid valves

- with proportional solenoid valve

- with absolute level signal

- with PID controlled flow

- Graphic LCD 204-128 Pixel

Ergonomics

With a comfortable keyboard, with large keys (22 x 22 mm), a clearly arranged display and the flexible functionality it is easy to realize simple as well as com- plex batch applications directly in hazardous area, without huge wiring expense to a e.g. panel room in safe area.

Simple remote control

It is possible to realize a remote control for the basic functions "START", "STOP", "RESET"

Process monitoring

The DC155 has a comfortable malfunction and disturbance monitoring system to monitor the sensor wiring and the flow.

To avoid wrong warnings, it is possible to turn off the monitoring for a programmable delay time at the start up phase.  This is also possible for over or under-run of limit values.

This is also possible for over or under-run of limit values.

Analog output

The analog output of the DC155 has a 14 bit resolution and it can drive an impedance up to 600 W, respectively 1000 W, using the separate analog output supply option.

MODBUS interface

With the modbus interface it is possible to view process data (like actual filled amout, total amount, etc) on a DCS for instance.