APM-2 Smart DP transmitter for pressure vessels

SKU: APM-2

Manufacturer: Aplisens

pdf datasheet

Overview

- Measurement of differential pressure based on two absolute pressure transmitters for level measurement in pressure tanks

- Modular construction with posibility of replacing of each module of the measuring system

- Output signal 4 ÷ 20 mA + HART

- Accuracy 0,1%

- Intrinsically safe and ex-proof versions

Application and Construction

The Modular electronic differential pressure transmitter APM-2 is applicable to hydrostatic measure of level in closed tanks, density or phase boundary.

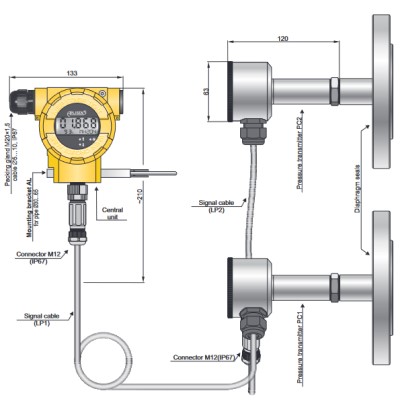

The measuring system consists of 3 separate modules – central unit and two absolute pressure transmitters.

The Level is calculated in central unit basing on measurement from two pressure transmitters. High pressure transmitter measures hydrostatic pressure of liquid in tank, low pressure transmitter measures pressure of gases above the liquid. Differential pressure is calculated in the central unit. With default settings of central unit function of high pressure transmitter is designed for transmitter directly connected with central unit (PC1). The User can change this assignment to second transmitter by changing configuration in central unit in local menu or via HART protocol. Measuring points can be several dozen meters apart.

The casing of central units is made of aluminium alloy cast or stainless steel with degree of protection IP66 or IP67 equipped with local display and buttons for configuration.

Measuring element of each of absolute pressure transmitters is piezoresistant silicon sensor separated from the medium by diaphragm and manometric liquid.

Process connection of absolute pressure transmitters can be diaphragm seal or threaded flush connection. By using diaphragm seals transmitters can be used for measurement of contaminated medium, medium with high viscosity, very hot or very cold medium or medium where sanitary process connection is needed.

Electronic units of pressure transmitters are closed in sealed stainless steel casings with degree of protection IP67.

All modules of measuring system are connected with electric cables (length of cables is specified by user). This system is an alternative for differential pressure transmitter with two remote diaphragm seals connected with capillaries filed with silicon oil uses in measurement of level on closed tank. The advantage of APM-2 is modularity of measuring system. By using M12 connection in case of any malfunction user has possibility to replace each of tree modules. Measurement is free of additional errors caused on the temperature gradient in the oil-based diaphragm sealing system. APM-2 transmitter gives not only information about differential pressure but also about static pressure and temperature (both transmitters and central unit.

Communication and Configuration

The communication standard for data interchange with the transmitter is HART protocol. Communication with the transmitter is carried out with a PC computer using HART/USB converter and RAPORT 2 configuration software. There is also possibility of configuration with using buttons and local display.

The data interchange with transmitter enables user to:

- identify the transmitter;

- setting LRV and URV by numeric value or by given pressure;

- zeroing of differential pressure measurement;

- change of measurement units;

- change of conversion characteristic;

- change of display configuration;

- read of differential pressure, static pressure of each of transmitters, temperature of central unit and each of transmitters;

- read of output signal in mA or percentage of measuring range;

- change of assignation of high and low pressure transmitters (PC1 and PC2);

- reset to factory settings.

Measuring Ranges

Nominal measuring range (FSO): 0...1 bar

Minimum set range (diff. pressure): 100 mbar

Admissible overpressure for pressure transmitters PC1 and PC2 (without hysteresis): 10 bar

Static pressure limit (depending on the set range of differential pressure): -0,9...1,4 bar for range 0...100 mbar, -0,9...0,5 bar for range 0...1 bar

Measuring ranges of pressure transmitters PC1 and PC2: 2,5 bar ABS