Dosing and Filling Stations

SKU: mid

Manufacturer: Bopp Reuther

Dosing and Filling Stations for oil and water based media - Palm Oil, Oils & Fuels and waterbased beverages, pharmaceutical and chemical liquids

pdf datasheet

pdf datasheet

Advantages:

- shortest filling time: < 0.1 second

- highest measuring accuracy: 0.01%

- lowest conductivity: >1µS/cm

- solutions for conductive and non-conductive liquids

- Palmoil, edible oils

- Oils, Fuels

- Purified water

- Beverages

- Chemicals, cosmetics

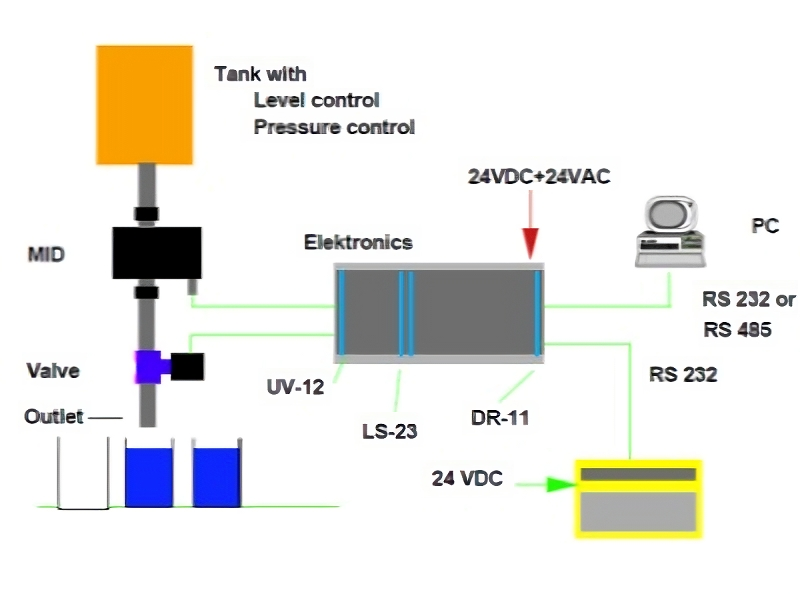

Complete Dosing Systems:

Complete Dosing Systems:

- Tank with level and pressure controller for storage of media for filling

- Flowmeter with Batch Controller for measuring the batch value and switching the batch, opt. PLC

- Valves to start and stop the batch

- Nozzle to avoid dripping

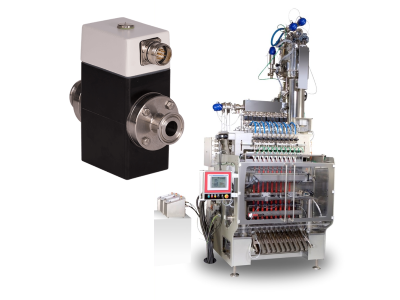

Compact Controller MID-PLC for Dosing Applications

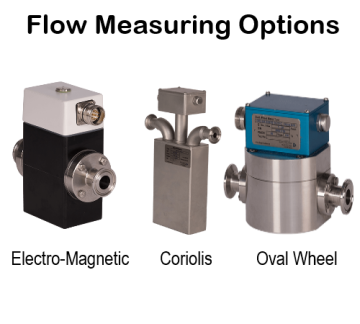

3 Fl owmeter options to measure the volume

owmeter options to measure the volume

- MID Electro-Magnetic: for water based media in Beverage, Medical, Pharmaceutical applications, very fast filling, accurate and highly sensitive 1ms

- Flowal OD oval gear for non conductive liquids , compact and robust design, Palm Oil Filling

- FMO Coriolis for non conductive liquids, oils, purified water, automatic zero point adjustment

Special Line Frequency Field Technology for MID Dosing:

MID Electro-Magnetic Flowmeters with the special line frequency field Technology (compared to switched DC field meters) have unique advantages for Filling & Dosing in the Beverage, Pharmaceutical and Chemical sector

- shortest filling time: < 0.1 second

- highest measuring accuracy: 0.01%

- lowest conductivity: >1µS/cm

Applications

|

|

|

|

Palm Oil, Oils, Fuels |

Yoghurt, Ketchup, Mayonaisse, Soups |

Dairy, Milk, Juices, Beverages |

|

|

|

| Cosmetics, Shampoo, liquid soaps |

Chemicals, Acids, Caustic Solutions | Pharmaceuticals, High Purity Water |