Shield lite Silo Protection System

SKU: Shield Lite

Manufacturer: Hycontrol

pdf datasheet

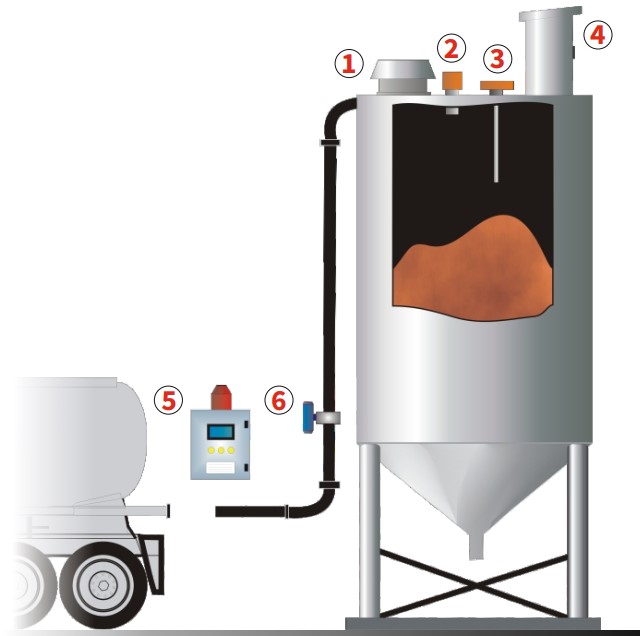

A silo protection system (SPS) is the name given to an interlinked collection of safety devices on a silo. In its most basic form, it should monitor pressure in the silo during a fill and take action to protect the vessel if anything goes wrong. The essential components of a standard SPS are as follows:

(1) Pressure relief valve (PRV)

(2) Pressure sensor

(3) High-level alarm probe

(4) Air filter (binvent or venting unit)

(5) Control and alarm panel at the fill point

(6) Shut-off valve on the fill pipe

SHIELD Lite incorporates essential high-accuracy pressure safety components into a modular design that can be adjusted to suit site requirements. Maintenance is simplified, and the long-term cost of ownership is significantly lower than any other system on the market. Along with many new features, SHIELD Lite incorporates Hycontrol’s pioneering Ground Level Testing system, in which a single key-turn enacts a full-function test of all the crucial safety components, dramatically reducing the need for working at height. Importantly the system is also wholly failsafe, a vital but often overlooked feature. The system can now even inform users if there has been an attempt to override the inlet safety valve.